THE VELOCITY PROCESS

Creating modernized restored vehicles that retain the classic pedigree with up-to-date performance and drivability.

Unrivalled Production Timeline

Velocity’s production process is broken into approximately one-week segments that correspond to a specific stage of restoration. Dedicated technicians at each station are specialists who ensure weekly progress and superior quality control. Engineering and Quality Control departments ensure both the build process and completed vehicles meet specifications.

In combination with a robust inventory of parts and vertical integration of all production elements, Velocity meets both quality standards and timelines like no other.

Body Mockup

Each vehicle starts as a bare frame that is powder-coated to ensure long-lasting durability. The vehicle body is then set on top of the frame to “mockup” the vehicle, this includes ensuring body gaps meet all requirements.

Exhaust & Roll Cage

Each roll cage is individually fit to the vehicle to ensure a seamless design. A custom exhaust system is also crafted to ensure your vehicle sounds as good as it looks.

Body Prep

Details matter and nowhere is that more apparent than in your body work. Each vehicle’s body is stripped to bare metal and body shop technicians correct and refine all panels. Priming, sanding, and bodywork preparation is completed for painting.

Paint

Custom Glasurit paint is sprayed on the body tub and panels of your vehicle. Velocity utilizes four down-draft paint booths in the paint facility to ensure the highest standard of finish. The underbody is sprayed with Raptor Lining for heat management and long-lasting protection.

Electrical

During this station each vehicle’s wiring harness is built and installed into the painted body. The dash and electrical components are also assembled and then installed into the vehicle.

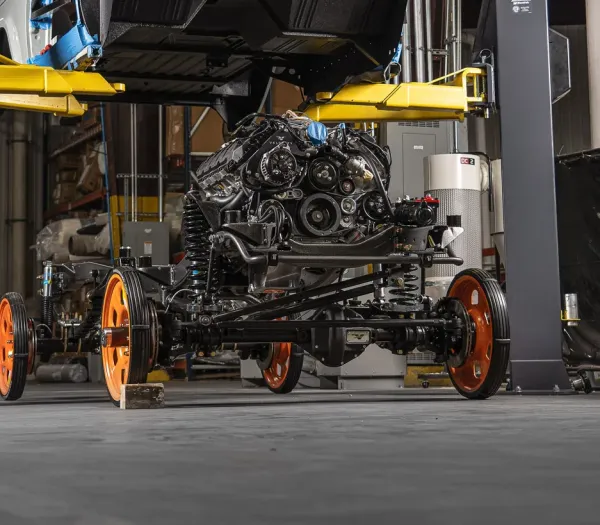

Chassis

While electrical technicians work on the body, new drivetrain and suspension components are assembled onto the frame. At the end of the week, the painted body is mounted to the completed chassis.

Mechanical

Technicians connect all electrical and mechanical parts of the vehicle. Depending on your model, the Ford 5.0L Coyote or Chevy 6.2L LT1 V8 engine is fired up for the first time allowing the vehicle to move under its own power to the next station.

Assembly & Trim Shop

During your build process, our in-house trim shop crafts the vehicle’s interior to your spec. In this station all components of your vehicle come together; the interior, body panels, roll cage, and bumpers are assembled and aligned.

Test & Tune

Dedicated mechanics oversee suspension alignment and test drive each vehicle 500+ miles to confirm break in is complete and make any needed adjustments. Each vehicle receives a custom tune on our in-house dyno to ensure an unparalleled driving experience.

Quality Control

Quality control technicians thoroughly inspect each vehicle, ensuring our industry leading standards are met. Any imperfections are corrected and tracked, and data is used to constantly improve the process.